Unplanned maintenance and emergency response

James Fisher Renewables has the expertise and assets necessary to assist our customers when the need for unplanned maintenance or emergency response arises. Our solutions prioritise safety, minimise downtime and reduce costs and offshore renewables assets around the world.

Services include:

- UXO ID and disposal

- Export cable fault detection

- Cable repair and replacement

- Diving and ROV

- Blade repair

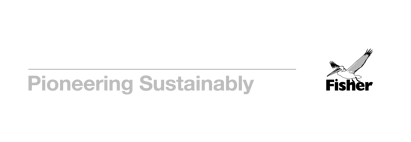

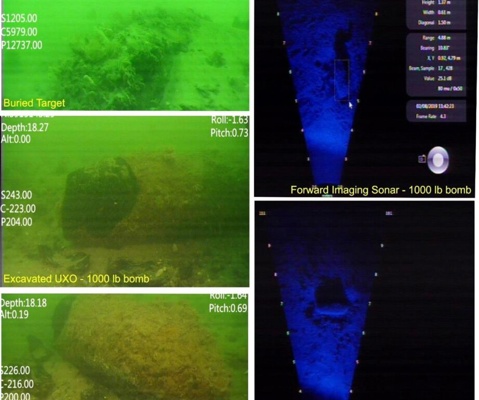

UXO ID and disposal

JF Renewables is highly experienced in the identification and disposal of UXO, having successfully completed projects in countries across Europe. Our skilled team offers an emergency response within 48 hours (subject to customer’s licence) and uses the latest technology to safely, rapidly and cost-effectively identify and remove UXO posing a risk to an asset.

Export cable fault detection

Monitoring export cables is a critical part of maintaining offshore assets, but a challenging task given the dynamic nature of the seabed. JF Renewables uses experience combined with cutting-edge technology (including DAS and Damped AC) to identify faults on export cabling and related infrastructure.

Cable repair and replacement

Our team of subsea cable repair experts are able to diagnose and repair a wide range of cable faults. Our full turnkey solution reduces downtime and gets assets back online as quickly as possible, minimising financial and reputational damage.

We operate a 24/7 control centre for fast response to incidents, with a team of over 70 highly skilled technicians who have access to the latest technology for accurate pinpointing of faults, both onshore and offshore.

Our capabilities include:

- Fault finding

- Cable recovery, storage and transport

- High voltage maintenance and management

- Re-burial

- Free span correction

- IRM services

- Cable jointing

- Cable termination

- Cable mitigation measures

JF Renewables is also highly experienced in post-failure analysis. We provide an independent technical report with a forensic breakdown, helping our customers establish the origin of the fault and take steps to minimise the chance of a repeat incident.

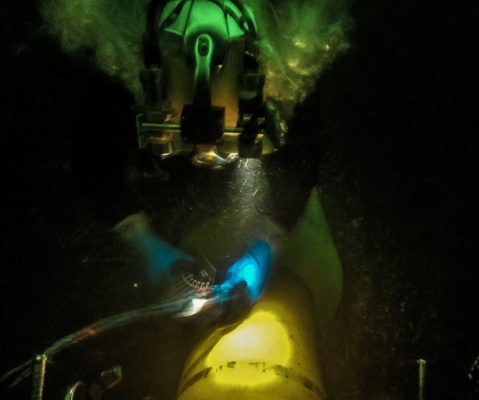

Diving and ROV

JF Renewables has access to experienced diving personnel and ROV systems with the capability to identify and access cables and other infrastructure quickly and efficiently, in order to carry out unplanned or emergency repairs to minimise downtime.

Blade repair

JF Renewables played a key role in developing the Gurit Renuvo UV cured blade repair method and has successfully completed projects in on and offshore environments using UV repair, which enables us to significantly reduce the amount of time required for curing. Benefits of UV blade repair include:

- Working temperatures can be 5 - 30 degrees Centigrade

- Fast curing - 25 times faster than Epoxy curing

- Clean materials - No toxic vapours emitted during curing

JF Renewables also conducts Epoxy resin wet layup repairs to our customers’ specifications. Using these materials and post-cure with heater blankets, we are able to carry out repairs to the highest standard. Our technical teams are highly experienced in carrying out repairs of this nature, and all our blade technicians are required to have at least four years’ referenced experience in blade repairs before we allow them to undertake turbine blade repairs.

Capabilities